Protective effect of zinc layer: Building an anti-corrosion barrier

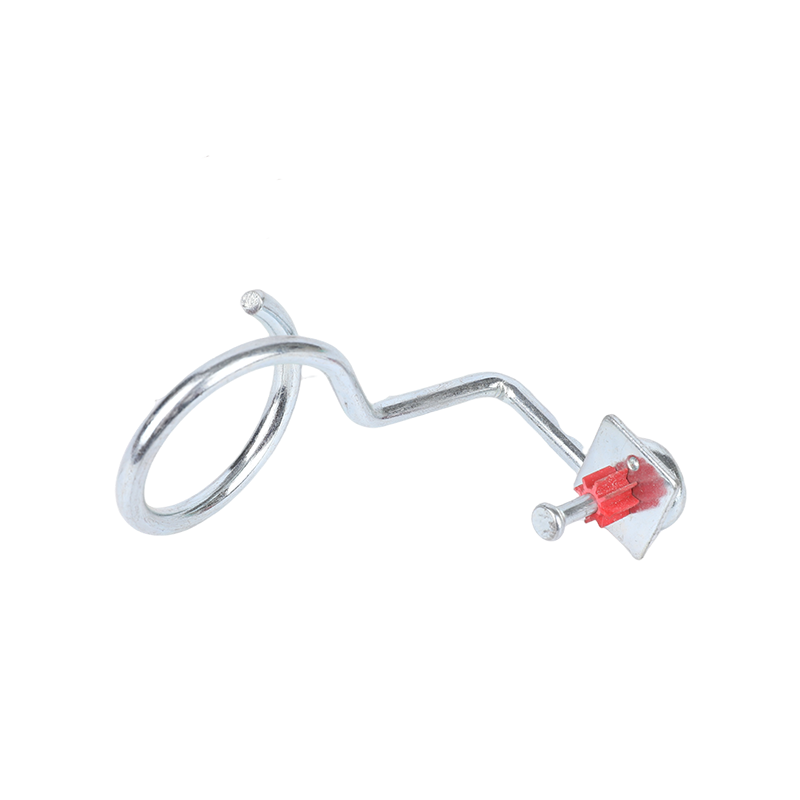

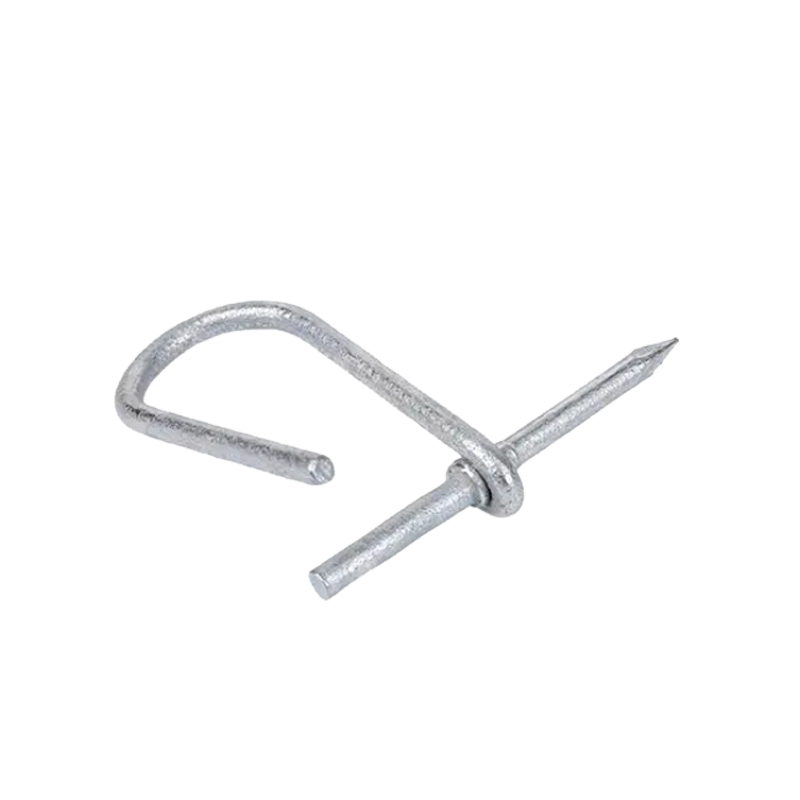

Electroplating zinc, as a common surface treatment technology, deposits a layer of zinc metal on the metal surface through electrochemical methods to form a tight and uniform coating. This zinc coating is not only beautiful, but more importantly, it can build a solid anti-corrosion barrier on the surface of the horse ring. In a humid or corrosive environment, the zinc layer can effectively prevent direct contact and penetration of moisture, oxygen and various corrosive substances, thereby slowing down or preventing the corrosion process of the horse ring substrate.

This protective effect of the zinc layer is due to its chemical activity. When the zinc layer is exposed to a corrosive environment, it will undergo oxidation reaction before the horse ring substrate (such as iron or steel) to form a dense zinc oxide film. This film not only further enhances the anti-corrosion effect, but also has a certain self-repair ability. Even if it is partially damaged, it can re-form a protective layer within a period of time, extending the overall protection time.

Extend service life: Improve economic benefits

This characteristic of electrogalvanized bridle rings greatly extends their service life in harsh environments. Compared with untreated galvanizing rings or similar products treated with other coatings, electro-galvanized galvanizing rings can significantly reduce the replacement frequency caused by corrosion, reduce maintenance costs and downtime, and thus improve the overall economic benefits. Especially in highly corrosive industries such as marine engineering, chemical industry, and food processing, the application of electro-galvanized galvanizing rings is particularly important, which is directly related to the stable operation and safe production of equipment.

Environmental protection and sustainability

In addition to excellent anti-corrosion performance, the electro-galvanizing process also has good environmental protection and sustainability. Modern electroplating technology is constantly optimized, using more environmentally friendly electroplating liquids and recycling systems, reducing the emission of harmful substances and reducing the impact on the environment. At the same time, zinc is a recyclable resource. After the electro-galvanized galvanizing ring reaches its service life, its zinc coating and substrate can be recycled and reused, which promotes the recycling of resources and is in line with the current development trend of green manufacturing.

Wide application field

The excellent performance of electro-galvanized galvanizing rings makes it widely used in many fields. In the construction industry, it is used to connect and fix structural parts to ensure the stability and safety of buildings; in automobile manufacturing, electrogalvanized bridle rings are key fasteners that ensure the tight connection and long-term reliability of various vehicle components; in the field of electronics and electrical, its good conductivity and corrosion resistance make it an ideal choice for circuit board connectors. In addition, in the fields of agriculture, aerospace, medical equipment, etc., electrogalvanized bridle rings also play an irreplaceable role.

English

English Español

Español